Gentle elemental forces

The water-operated alljig® jigging machine is efficient and reliable in operation. The alljig® fluidizes the feed material by pulsating water forming layers of grains according to their density and subsequently separates the heavy material from the stratified material bed.

Electronic sensors are used to automatically monitor and control the precise discharge of heavy particles contained in the feed. alljig® jigging machines create a physically stable and individually adjustable optimal jigging stroke at minimal energy consumption by means of air-pulsed water.

These machines provide capacities ranging from 5 tph up to 700 tph. The process of efficient separation and cleaning of feed material is applicable to grain sizes from 150 millimeters down to less than 1 millimeter.

The alljig® is capable of handling a large variety of primary and secondary raw materials such as coal, ore, gravel, sand, slag and various other recycling materials. The only prerequisite for an optimal separation is a difference in particle density within the feed material. Furthermore this innovative system is particularly user-friendly, requires little maintenance, saves energy and operates at minimal cost.

More than 500 alljig® jigging machines sold in 25 years are facts that speak for themselves as best reference.

Gallery

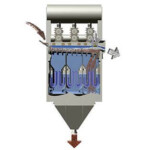

Schematics

Separation of minerals in jigging machines is based on the fact that particles will stratify in pulsating water. The upward and downward currents fluidize and compact the grains into relatively homogenous layers. Low density pieces stratify on the surface, while specifically heavy grains settle to the lower level of the bed. Depending on the application and the feed particle size, the discharge is realized by means of a movable bed, bottom gate, star gate or vibrating feeder discharge.