The lightness of being

The allflux®-process makes sophisticated use of the laws of physics: the method is based on the fluidized bed principle. The allflux® separator separates lightweight material made of fine-grained substances; e.g. sand. The allflux® treats the material in a two-step process, eliminating the need for pre-thickening. One single system combines high efficiency and high throughput.

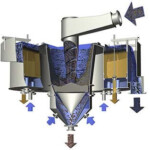

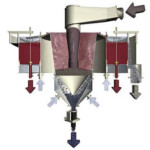

The system is very simple: the allflux® generates an upward current in the coarse sand chamber. Light and fine particles rise while coarse, heavy particles sink and are drawn off. In the fine sand chamber, which is the second stage of the process, fine particles form an autogenous fluidized bed on which the lightweight material to be separated floats and spills over a weir. The fine sand product is discharged automatically from the bottom of the fine sand chamber. The flow and control equipment facilitates the generation of three highly selectively graded products by one machine. Process control is automatic.

The allflux® has a throughput capacity of up to 2,000 cubic meters per hour. A top size of up to four millimeters can be easily processed. The advantages of the allflux® have won recognition worldwide: sorting, separating, thickening and cleaning in one single step – the system speaks for itself.

allflux® technology can be used for sand, coal, ore and mineral sands.

Schematics

The two-step process permits the handling of slurries without pre-thickening. The coarse and heavy particles are separated in the coarse section. Fine material and low-density particles overflow the coarse separation section. In the peripheral fine section the separation of light particles from the fines and desliming takes place. Particles of a lower specific gravity than the fluidized bed will remain above the fluidized bed and will overflow with most of the process water to the overflow chute.